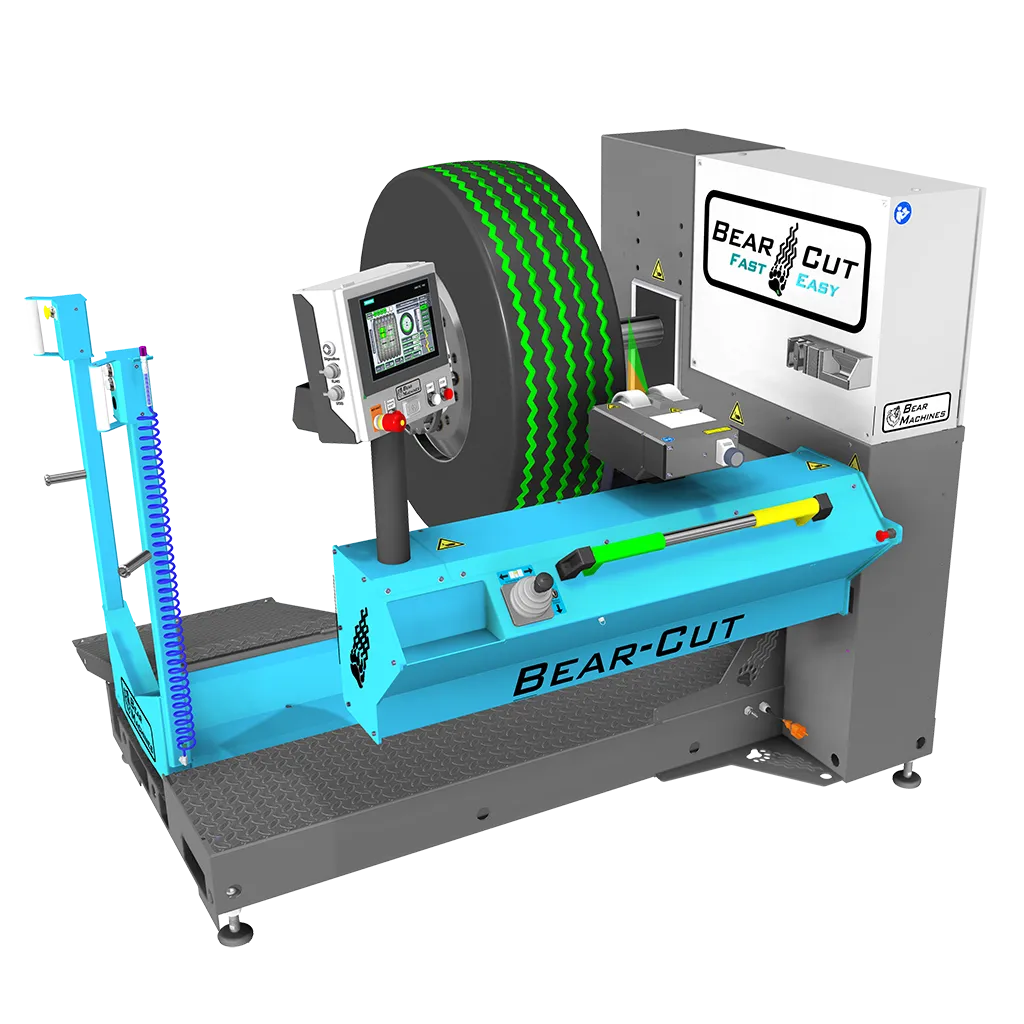

Bear-Cut:

Tire reprofiling

effortless, fast & sustainable!

Extending the life of your tyres and saving CO₂

Quick and easy regrooving (regrooving) of commercial vehicle tires with the regroovable label.

Life extension of at least 25 %

Regrooving a tyre and extending its life by at least 25% means buying fewer new tyres.

Positive for CO₂ balance and wallet

A regrooved tyre consumes less fuel, which has a positive effect on the CO₂ balance and on the wallet.

Bear-Cut.

Now with improved technology.

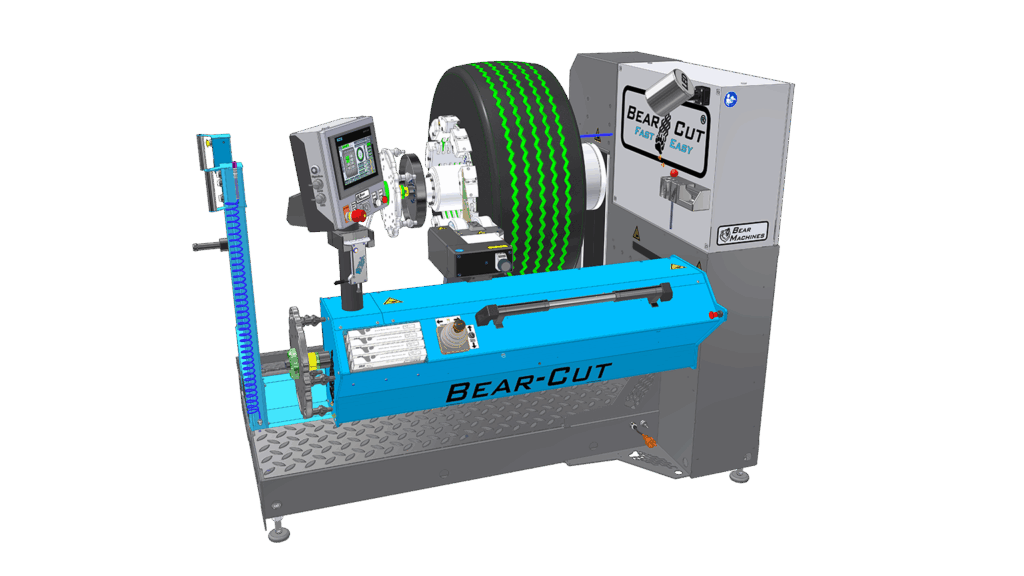

Bear-Expander

New clamping system:

Clamp tires with or without rims

Automatic Bear-Caliper:

Simply transfer the cutting depth to the control system

Software-Update:

Tires can be recut almost fully automatically

New loading method:

The tire can be loaded from the front—ideal for mobile use on a truck

What our clients say

Gerhard Röger

Stefan A. Eisenhofer Transporte

Alexander Schuon

Alfred Schuon GmbH

Andreas Oppel

Spedition Oppel GmbH

Thomas Oppel

Spedition Oppel GmbH

Peter Lüdorf

Gummi Berger Gruppe

Stefan Eisenhofer

Stefan A. Eisenhofer Transporte

Georg Wittwer

Wittwer Spedition & Logistik GmbH

Patrick Bröckers

spieker products GmbH

Dirk Werner

Verkehrsgesellschaft Kreis Unna (VKU)

approx. 13m groove is recut per tyre / 705 kg CO₂ is saved per recut tyre.

* The formula for the calculation of the CO₂ value is composed as follows

Mark Berendsen

Managing Partner

With our Baer-Cut machine, we create efficiency and many advantages for hauliers and fleet managers who have commercial vehicles in use. By continuing to use existing tyres, our customers save money. At the same time, this is sustainable and ensures a better environmental balance.

Mark Berendsen